Smart water affairs

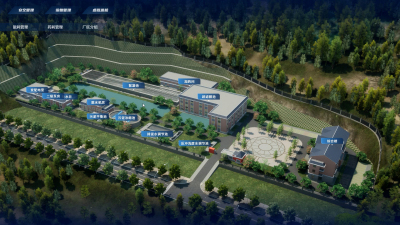

- Through the integration of real-time rendering technologies and vividly realistic animations, we can simulate factory buildings, underground pipelines, and dynamic process flows with authentic details. This allows us to construct a three-dimensional, visualized virtual water plant within a digital space. With a focus on energy savings, cost reduction, and enhanced management, we consolidate all types of static and dynamic management data. This enables the intuitive display of key data and performance indicators across all stages of water supply. As a result, we provide comprehensive support for the entire business process of urban water supply, from raw water procurement, through water treatment and distribution, to drainage, wastewater treatment, and water conservation. This approach significantly increases the operational efficiency of water utility companies.

Industry Pain Points

From macro to micro, we replicate all elements of the water plant, including its architecture, environment, pump rooms, equipment, and pipelines. We conduct comprehensive monitoring and analysis of key indicators, including water quality information, chemical consumption information, energy consumption information, alarm information, and the operational status of equipment.

Integrating the security surveillance system involves deploying various security devices such as cameras, access controls, electronic fences, and more in a multi-dimensional and comprehensive layout at the water plant. This setup allows for an intuitive visualization of the security monitoring environment, with alarm data consolidated into a single dashboard. It also supports the review of historical records for temporal backtracking.

Additionally, real-time video streams are integrated with the virtual scene, applying boundary blurring to create a seamless connection between the virtual world and the real world. Through this virtual system, the actual operations of the water plant can be monitored.

Display the status of all equipment in real-time on a comprehensive view of the facility's operations, implement unified management throughout the entire lifecycle of the equipment, achieve real-time monitoring of facilities and equipment status, perform maintenance as needed and preventive maintenance, and reduce the probability of equipment failures.

On the basis of a three-dimensional digital twin of the surface structures of the water plant, support the visualization of underground pipeline routes and concealed structures such as riser pipes. Enable the display of real-time monitoring data and specific locations of devices such as flow meters, pressure gauges, and water quality instruments distributed along the underground pipelines, as well as alerts for sensor readings exceeding threshold values.

Based on a highly realistic digital twin scenario and the operational needs of the water plant, adopt virtual inspections to replace traditional manual inspections. Conduct production facility inspections for the water plant without leaving the premises, and display the inspection data on the platform, standardizing the management of inspection work.

Dynamic simulation of water intake systems, filtration systems, dosing systems, sludge systems, water delivery systems, and ultrafiltration membrane systems for water treatment processes. Visualization presents the water treatment process flow, enabling a comprehensive understanding of the water purification process in a single diagram.

Integrated Monitoring Dashboard

Process simulation

Safety management

Device management

Pipeline analysis

Virtual inspection

Classic case

Smart water affairs

A water purification plant in Zhejiang Province

Smart water affairs